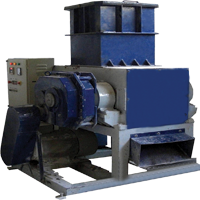

These machines are ideally suited for

- Crushing of large lumps without precutting

- Crushing of hdpe pipes of diameter thickness say. 60mm & length 2.5 meters without precutting.

- Wood scraps can also be granulated to small chips

Principal Operation

- The cutting chamber has rotor with multicutters bolted onto the rotor. The blades on the rotors are square shape having 4 indexable edges.

- The rotor drive system consists of foot mounted motor which drives SMSR (Shaft Mounted Speed Reducer) through pulleys. The SMSR is mounted on rotor shaft .The rotor shaft rotates at about 80 rpm.The SMSRr takes care of impact loading of the rotor cutter by means of rubber bushing suspension system.

- The rpm of rotor is approximately 80, obtained by SMSR (Shaft Mounted Speed Reducer) & V belt drive through motor.

- The fix blade is fitted into the cutting chamber. The fix blade has multiple V grooves (Angle 90º)

- Thick pipes, lumps are fed manually or through conveyor into the cutting chamber via hoper.

- The reciprocating ram (with adjustable feed) presses the articles against rotor blades & fix blades, there by granulating the pipes, lumps or articles into small chips.

Silent Feature

- The hydraulic cylinder is suspended by cardanic joint (universal joint), which takes care of uneven load on ram & reduces the unnecessary wear on piston seals, rod seals, thereby increases the life of hydraulic cylinder.

- The feed of the reciprocating ram can be adjusted by hydraulic valve, as per the load & if the load on cutter increases, the ram stops feeding into the cutter & reverses into open position.

- During cutting operation, if the material is jammed in between the rotary & fix blades, there is a provision to reverse the cutter direction of rotation, there realising the jammed material

- The bearings are spherical & located outside the chamber so that it can take up mis alignment & the dust generated by shredder does not enter into the bearings.

Specifications

| No. | Model No. | 6026 Hydraulic Feed | 8026 Hydraulic Feed |

|---|---|---|---|

| 1 | NO OF ROTARY BLADES | 30 | 28/42 |

| 2 | SIZE OF ROTARY BLADES mm x mm | 40X40 | 40X40 |

| 3 | RPM OF ROTOR APP | 85 | 80 |

| 4 | NO OF FIX BLADES | 1 | 2 |

| 5 | LENGTH OF FIX BLADES mm | 570 | 388 |

| 6 | ROTOR DIA mm | 260 | 260 |

| 7 | INFEED OPENING Wmm x Lmm | 550x650 | 750x750 |

| 8 | CUTTER MOTOR HP | 30-40 | 40-50 |

| 9 | HYDRAULIC DETAIL | ||

| 10 | STROKE | 470 | 600 |

| 11 | MOTOR FOR HYDR.POWER PACK HP | 2 | 5 |

| 12 | OUTPUT* KG/HR | 200-300 | 350-500 |

| 13 | SIEVE HOLE DIA mmxmm | 40x40 | 75x75 |

| 14 | APPLICATION | (A)LUMPS HDPS-PP-PVC,PC,ABS,Size: Lmm x Wmm x Tmm :900x420x90 (B)LUMPS HDPS-PP-PVC,PC,ABS,Size: DIA mmx THICKNESS mmx LENGTH mm 450x75x2000 (C)HALF DRUM HDPE (200 LTIRE) | (A)LUMPS HDPS-PP-PVC,PC,ABS,Size: Lmm x Wmm x Tmm :900x750x90 (B)LUMPS HDPS-PP-PVC,PC,ABS,Size: DIA mmx THICKNESS mmx LENGTH mm 710x70x2000 (C)HALF DRUM HDPE (200 LTIRE) |